Digital automatic coupling (DAC) – background and opportunities

Digital automatic coupling (DAC) is modernising rail freight transport: it makes coupling safer, faster and more efficient. The roll-out requires Europe-wide coordination and, as things stand today, not all technical issues have been adequately addressed which is making its introduction a mammoth task for the sector.

What is the digital automatic coupling?

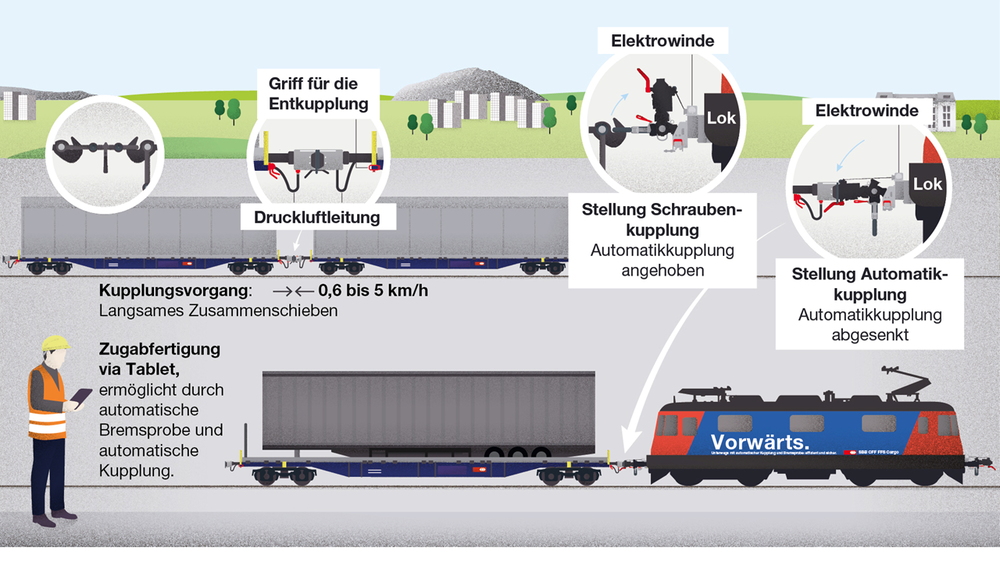

As shown in Figure 1, the digital automatic coupling (DAC) replaces the time-consuming manual coupling using screw couplings. It automatically connects freight wagons – including the brake air lines and an additional power and data line – and at the same time enables fully digitalised train preparation. The DAC offers enormous advantages, particularly in single wagon load transport, where wagons often have to be rearranged.

Digitisation of train preparation leads to cost savings.

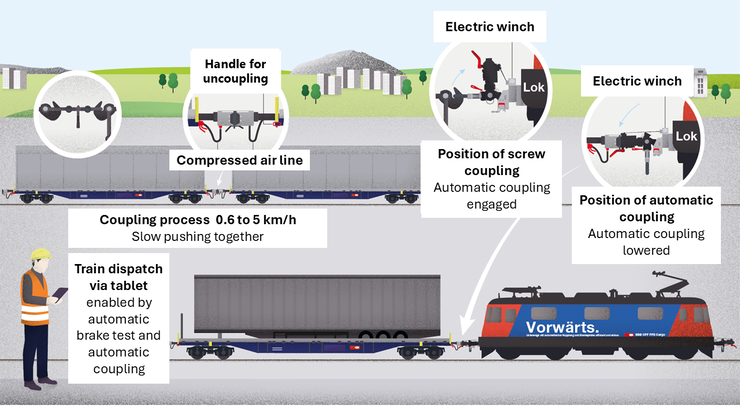

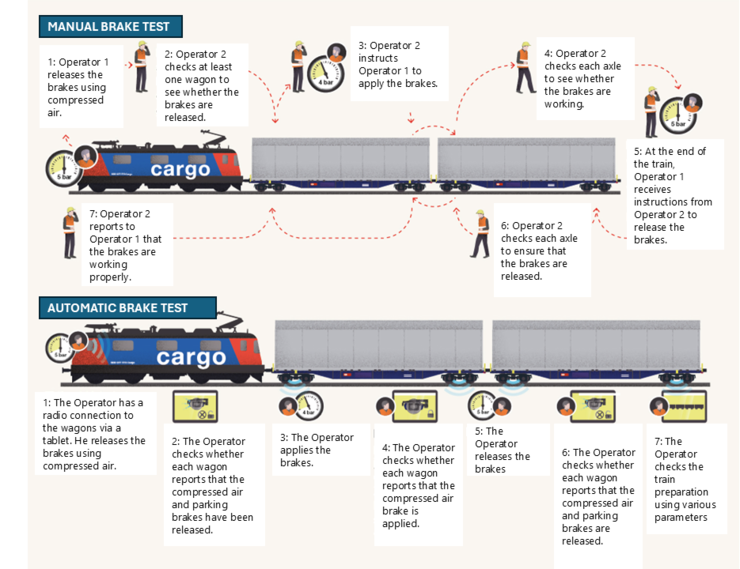

Before a freight train can depart, numerous manual checks need to be carried out, and documentation completed in addition to coupling. DAC creates the conditions for automating these processes in accordance with Figure 2 – such as brake testing, recording the wagon sequence or inspecting the wagons – which drastically speeds up train preparation: from 2–3 hours previously to just 20–30 minutes. This benefits block trains in particular, because their processes become much more efficient as a result.

Figure 2 shows how a manual brake test differs from an automated brake test. It takes two employees to do the manual brake test. The first employee first releases the brakes using compressed air, then the second employee checks at least one wagon to see whether the brakes are released. The first employee then applies the brakes, and the second employee checks each axle to see whether the brakes are working. The first employee then releases the brakes, and the second employee checks each axle again to see whether the brakes are released.

This process can be greatly simplified with the help of automatic coupling. An employee can use a tablet to check whether the compressed air and parking brakes on each wagon are released. After braking, the tablet can be used again to check whether the brakes have worked. Other train parameters can also be checked directly using the tablet.

How digital automatic coupling is changing rail freight transport.

In order to compete with road and other modes of transport, rail freight transport needs more digitalisation and automation. The digital automatic coupling (DAC) is the key to a more flexible, efficient and sustainable freight transport system. Since autumn 2020, responsibility for introducing the DAC has lain with the European DAC Delivery Programme (EDDP) which was initiated by the European Commission. All key players in European rail freight transport are involved in this programme. The aim is to have all freight wagons and locomotives across Europe converted by 2030. Within the ‘DACRail’ database, Wascosa, together with other wagon keepers, is currently collecting information on which freight wagons are suitable for conversion.

A coupling for the whole of Europe.

To ensure the quality of the new coupling, the EDDP put several prototypes through their paces. In Germany, over 400 different coupling tests were carried out on each type at a test site. At the same time, the four types were tested for winter suitability in northern Sweden. Ultimately, the decision was made in favour of the Scharfenberg coupler head. This is to be produced by various manufacturers which will ensure that the system remains manufacturer-independent and accessible to all European operators.

Why the introduction of digital automatic coupling (DAC) remains a challenge.

Despite the obvious advantages, its introduction has been slow so far. The main reasons: lack of funding and limited efficiency savings in the early stages of development. However, it is now clear that DAC improves not only safety but also the competitiveness of rail freight transport. Particularly in the wake of the energy transition, which is reducing the transport of coal and mineral oil, the rapid transport of time-critical goods such as consumer goods is becoming increasingly important. Intermodal transport will become increasingly important. In Germany, the modal split of rail freight transport is currently around 18% – by 2030, it is expected to rise to 25%. This can only be achieved with a corresponding increase in efficiency through automation.

Coordination and financing as the key to success.

The switch to DAC requires considerable investment. Since DAC trains are no longer compatible with conventional screw couplings, it is essential to closely coordinate migration between all EU countries and Switzerland. The conversion phase should be kept as short as possible to ensure smooth operation. In Switzerland, the project ‘Automation in Swiss rail freight transport – migration to digital automatic couplings’ was launched in 2021. The Swiss Federal Council recommends that 30% of the conversion costs be financed by the state. The current plan is to convert approximately 14,000 to 18,000 freight wagons and 500 locomotives in Switzerland. In Europe, the figure is 430,000 to 480,000 freight wagons and around 17,000 locomotives.

Conclusion: The digital automatic coupling (DAC) is an investment in the future.

Digital automatic coupling is more than a technical innovation – it is the key to modernising European rail freight transport. With its help, rail freight transport will become faster, safer and more digitally connected – and will finally be able to catch up with other modes of transport.

Please also read the interview with Stefan Hagenlocher, project manager of the Technical Innovation Circle for Rail Freight Transport (TIS) and Managing Director of hwh Gesellschaft für Transport- und Unternehmensberatung mbH, in our Wascosa infoletter no. 36.