The future belongs to modular logistics concepts

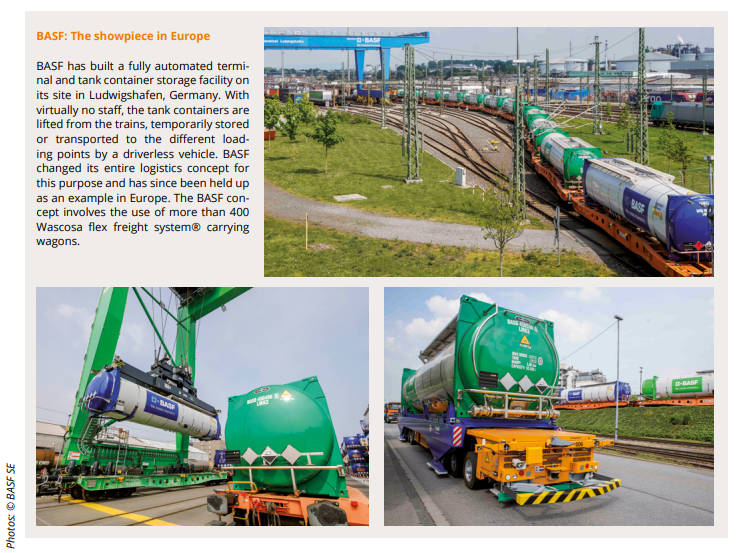

Modular systems offer large companies enormous efficiency gains in rail freight transport, because the big costs occur in the first and last mile. In this respect, BASF has been a pioneer and a success story that shows what is possible when an entire logistics concept is optimised using modular systems and automation.

“Dismantling a freight train and bringing the individual wagons to the loading points – some of which are kilometres apart – is time-consuming and cost-intensive,” explains Stefan Hagenlocher, Project Manager of the Technical Innovation Circle for Rail Freight Transport TIS and Managing Director of hwh Gesellschaft für Transport- und Unternehmensberatung mbH in Karlsruhe. Many special freight wagons are also used as temporary storage facilities for the transported goods. They often stand around for days until they are finally unloaded before returning to their place of origin empty or with a new load.

Lower investment, maintenance, and operating costs

Modular freight wagon systems are significantly more efficient: because there is no fixed connection between the carrying wagon and the container, the container with the transported goods can be removed from the wagon and stored temporarily without any problems. The carrying wagon, however, can be immediately reloaded with new containers. The savings potential is considerable: “If we assume that a company will only need 1,000 carrying wagons instead of 2,000 special freight wagons in the future, it can significantly reduce its investment, maintenance, and operating costs, even if it has to use 3,000 containers,” explains Hagenlocher.

The increase in productivity is reflected in the mileage: while special freight wagons have an average mileage of just 30,000 to 50,000 km per year, modular, standardised carrying wagons cover three or four times that distance, i.e. 150,000 to 200,000 km per year.

Standardisation of the interface

A working group within the Technical Innovation Circle for Rail Freight Transport (TIS) is currently working on a possible standardisation of the interface between the carrying wagons and containers/superstructures of the modular freight wagon systems: “It will take some time before we have a European standard,” explains Hagenlocher, “but from my point of view modular systems will be essential in the future.”